Indiviaul 3d design and printing

I observe all the test in group assignment then according with that settings I did my indiviual design and printing.I like jwellary so I make design of bangles and finger ring.

Step for design

first I watch some designs on website then I select one design of bangle because i like to design jwellary but in solid work i firstly design the jwellary i was ecxited for this.I watch some video of making jwellary in solid works and then i make design.

Steps

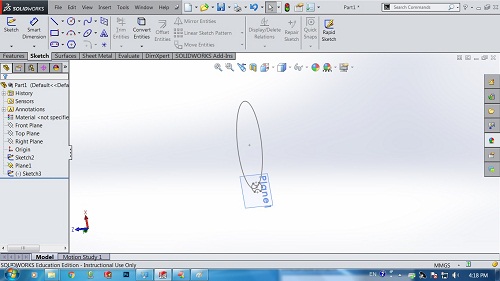

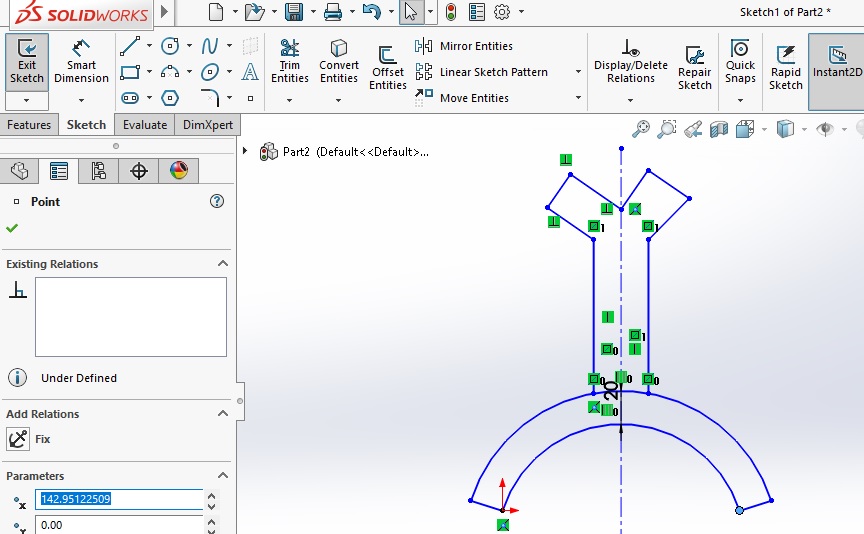

Open solid works then create new file then take select plane,then take circul.make a point on edge of circul then I make that point as origin and draw one other circule there.

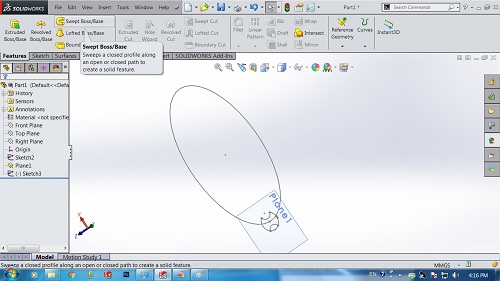

after that i go on swept command then i first choose the profile then i choose the path and said yes

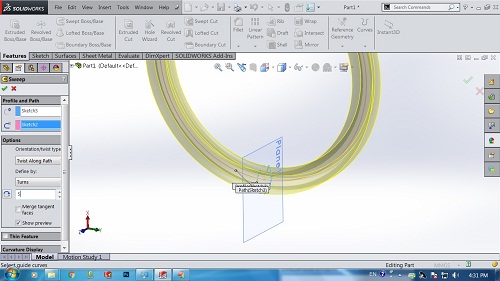

After this I select the the option menu and there is one option i.e twist follow path then there is one other option i.e turns then i put the value 5 and said yes.

after click on yes it creats a solid file.

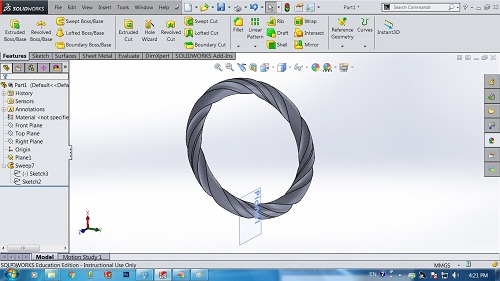

This is my final bangle design now it is ready for 3d print i save this design as .stl

steps for 3d printer

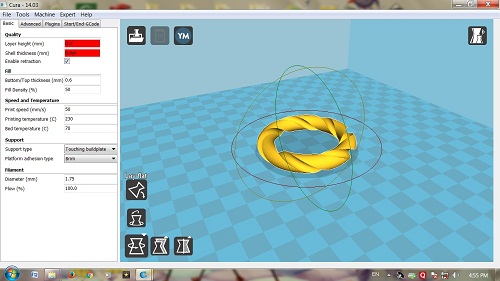

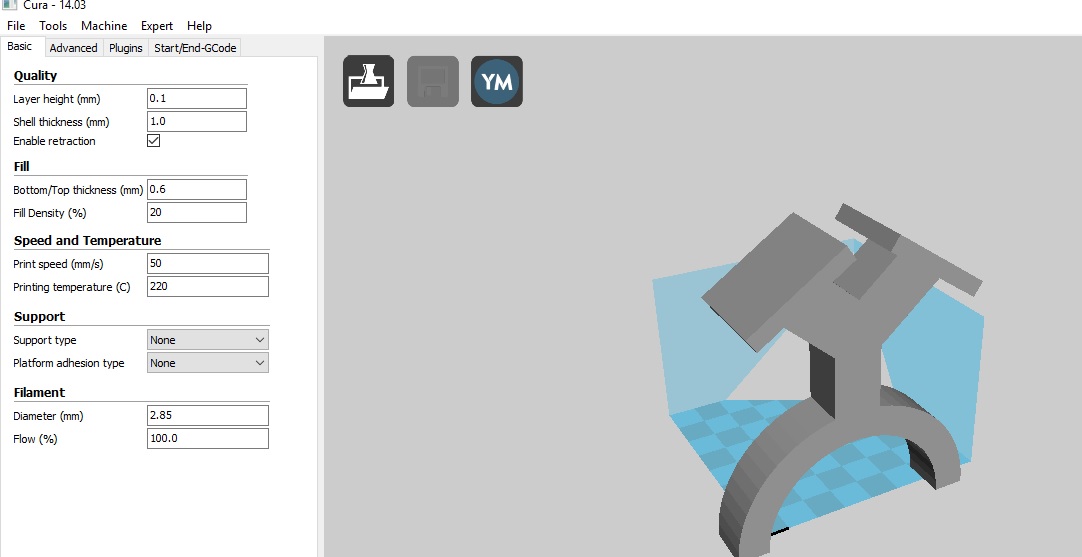

I used accucraft 3d printer but we cant go directly to the printing first we have to create a gcode of that design.I use 3 software cura then kisslicer and repetior host

first i open the cura software for giving the position to my object ,i insert image in cura i rotate that image then said lay flat i save this image as .stl

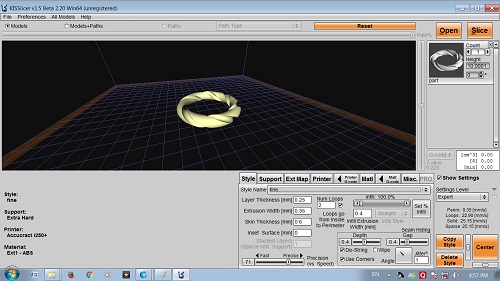

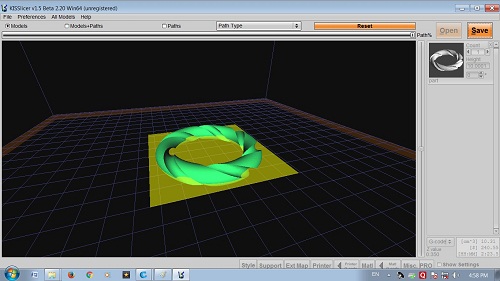

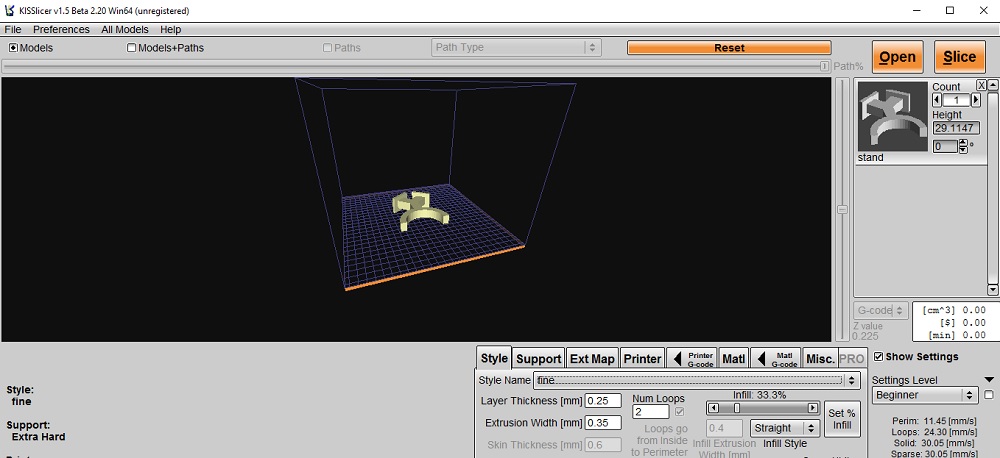

After this I used kisslicer to slice the object and gives the different settings like layer thickness,infill,support on/off etc we set this settings according with our object.

After putting the settings i save this file and it creats the GCODE after save the software again slice the object.

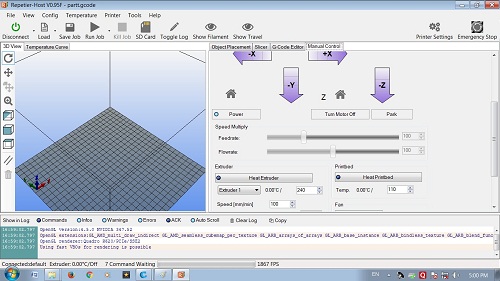

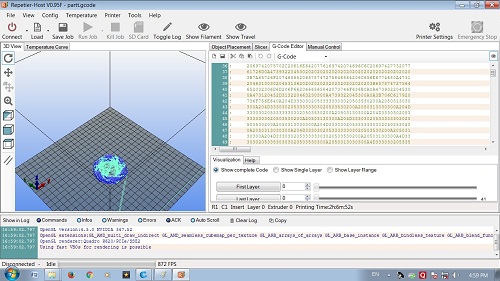

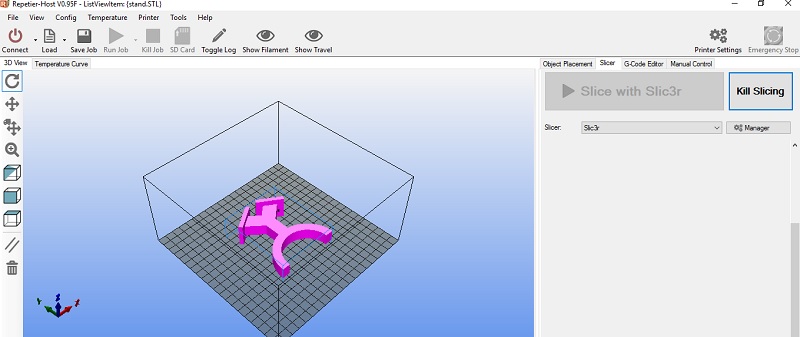

Then i open repetior and insert the final print objects gcode then i connect printer with laptop and i first go to the home position then i heated a bed and extrude also by using there own commands.after heat the bed i go the run job and prints start.i put stick on bed

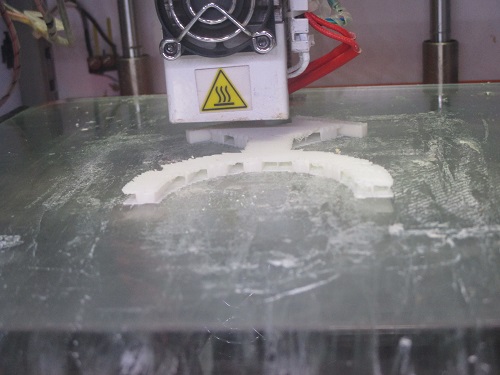

Because of extra heating of extruder the material get burned then i minimize the temp. i bring temp.at 225°c for extruder and 74°c for bed and this works very well.

This is my final product from 3d printer.

Twisted object cannot be made by the substractive method so i use 3d printer to make this project.

Project part

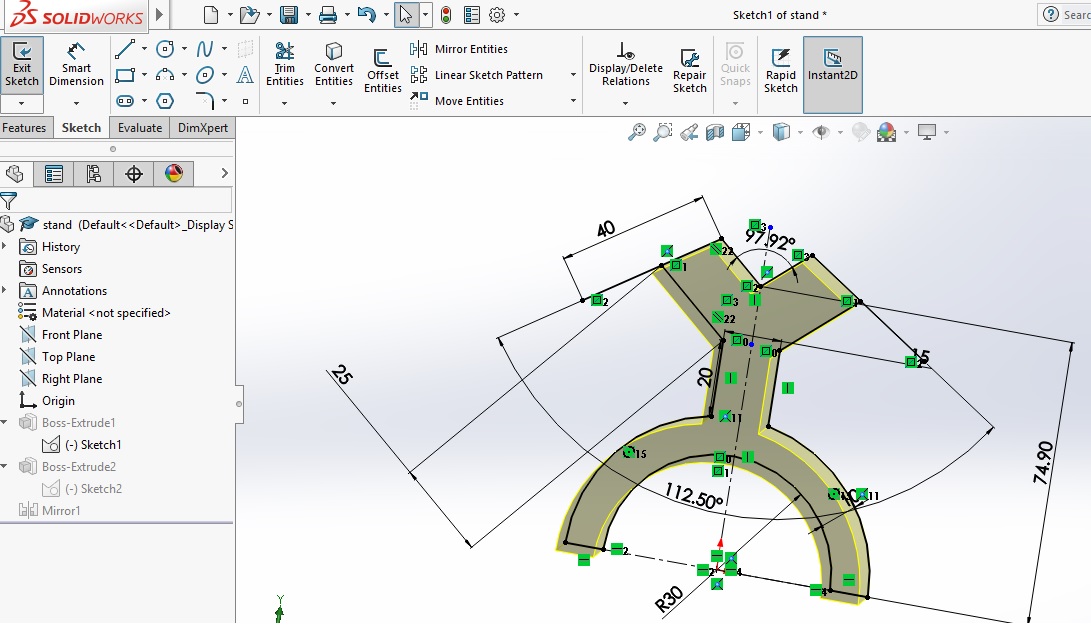

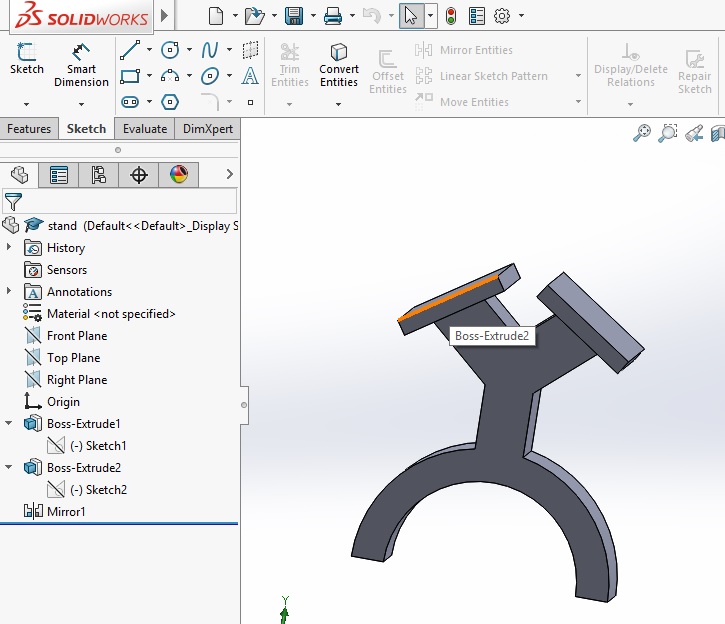

In my project i want to make the panel holder with some angle,so i design the panel holder in solid works for that first i select the plane then choose arc and make the center line then i draw the center line then i draw the same design on both the side of center line using mirror command.

then i extrude this part

then said okay

After this i save that file as .stl then to set the orientation i import this file in cura.

To set the infill and set the support i open my file in kisslicer then i set the infill at 33% and slice .it make the g-code

then i import that file in repitior host for printingthen i save that file to sd card

I bring temp.at 225°c for extruder and 74°c for bed and this works very well.

my panel holder is now ready

the final project part made by me is very nice it is very usefull for me and i learn here how use the 3d printer